Audio Engineers Booster Fluidium Isolation Pads

Adaptive crystal particle damping technology.

Booster Fluidum isolation pads are an advanced version of the Booster Kinetic series that can adapt to different vibrations in a wide frequency range, thus providing more effective damping. Booster Fluidum isolation pads are made of unique materials and use special adaptive crystal particle damping technology. Each Booster Fluidum isolation pads incorporates Audio Engineers’ unique design principles to deliver unbelievable results, providing optimal particle damping.

Booster Fluidum isolation pads are capable of effective 2-way damping and adaptive particle damping provides more efficient and wide frequency-range vibration absorption than previous solutions. Booster Fluidum isolation pads effectively dampen the audio devices’ own resonances and vibrations from the environment.

Booster Fluidum isolation pads are designed for audio- and video devices, projectors, turntables, subwoofer, center-, and bookshelf speakers. Booster Fluidum isolation pads are designed to provide adaptive vibration damping and enhanced sound clarity over a wide range.

Advantages of adaptive crystal particle dampers:

They are able to perform over an extremely wide frequency range, unlike viscoelastic or general hard-point dampers, which are highly frequency dependent.

They are capable of effective damping over a wide weight range, in contrast to viscoelastic materials, which are highly weight dependent.

They are able to adapt to the characteristics of the vibrations, so the hardness of the damping changes accordingly.

The free movement of the adaptive crystal particles simply converts the vibrational energy into heat.

Virtual analyses can be used to develop particles of the most appropriate type, size and consistency for a given application, therefore, they can be used for applications where accuracy, high efficiency and long operating time are required.

They are able to operate over a wide load- and temperature range without loss of efficiency.

Particle Damping

The principle behind particle damping is the absorption of kinetic energy through losses, which results from the displacement of granular particles which move freely.

Particle damping is most similar to the behavior of gravel thrown into the sand on the beach, where the sand particles immediately reduce and dissipate the kinetic energy of the impact. Particle damping technology is one of the most advanced solutions of impact and vibration damping with several advantages. General damping is performed by only a single mass, while in the case of particle damping, several small auxiliary masses perform this task.

The particle dampers are highly non-linear dampers whose damping, is derived from a combination of loss mechanisms, including friction and momentum exchange, which dissipate the vibrations into heat. Because of the ability of particle dampers to perform through a wide range of temperatures and frequencies and survive for longer life, they have been used in applications such as the weightless environments of outer space or in aircraft structures.

State-of-the-art materials and technologies

Booster Fluidum isolation pads use a highly efficient combination of materials and technologies used in advanced industry.

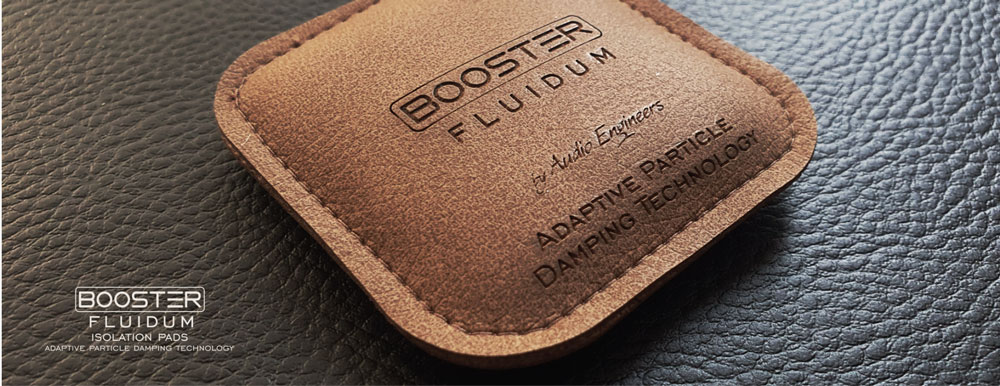

The outer cover of the Booster Fluidum isolation pads is made of a multi-layered, special, leather-effect material that is reinforced with an inner textile layer. The outer cover is cut and inscription accurately using a laser process, and the layers are sewn with an extremely strong polyamide fiber, which is also used in parachuting.

The fine-grained silicon dioxide crystal particles used in Booster Fluidum isolation pads are coated with a special polymer, which increases the cohesive force between them. Due to this, the behavior of the particles is partly similar to the properties of non-Newtonian fluids. The particles become hard from sudden forces and soft in the case of continuous slow vibrations. Due to this property, they are able to react to different vibrations with different damping characteristics, so provide extremely efficient particle damping over a wide frequency range.

Made by hand

Each Booster Fluidum isolation pads is handmade in the EU. After the last quality control, the Booster Fluidum isolation pads sets are placed in an exclusive aluminum box.

Features

Effective 2-way damping

Effectively reduces devices vibration

Effectively reduces vibrations from the environment

Adaptive crystal particle damping technology

More accurate imaging and extensive soundstage

More spatial detail and low noise

Increased dynamic range

Specifications

Special leather-effect multi-layer outer cover

Precisely sized silicon dioxide crystal particles with a special polymer coating

Laser machined and made by hand

Color: Camel

Dimensions: 2,5″ x 2,5″ x 0,6″ / 65mm x 65 mm x 15 mm (approx)

Load capacity: 22 lbs / 10 kg / 1 pc

Available in a set of 3 or set of 4